Sustainable, affordable and fast construction with TwistBlocks!

TwistBlocks

We sell TwistBlocks in our local factories

TwistBlocks

Lower construction costs – faster construction completion: Certified by Kenya Bureau of Standards

Resources for your

TwistBlock Project

Building

Economics

The Start Somewhere TwistBlocks offer many advantages compared to standard masonry construction without being more expensive. Due to the clean finish there is no need for plastering.

Advantages

Why you should use TwistBlocks

TwistBlocks

Positions:

Labour

SSW Twistblocks

Standard Plastered Masonry

Positions:

Labour

Mortar

Formwork

Steel / Concrete

Plaster

Stones

REUSABILITY

of the TwistBlocks and therefore total ownership.

CLEAN FINISH

no need for plastering.

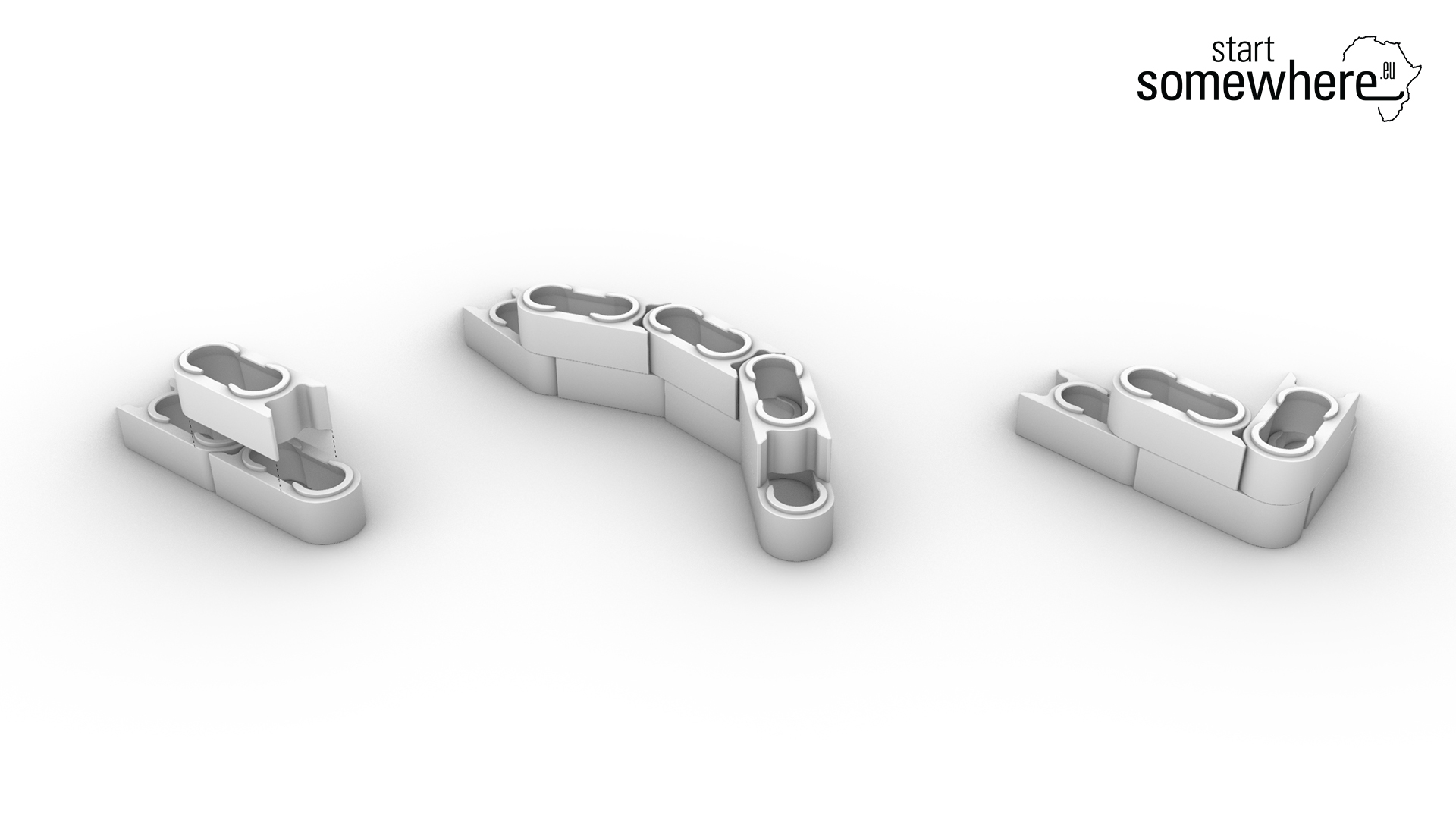

BUILDING SPEED

up to 10 times faster than standard masonry.

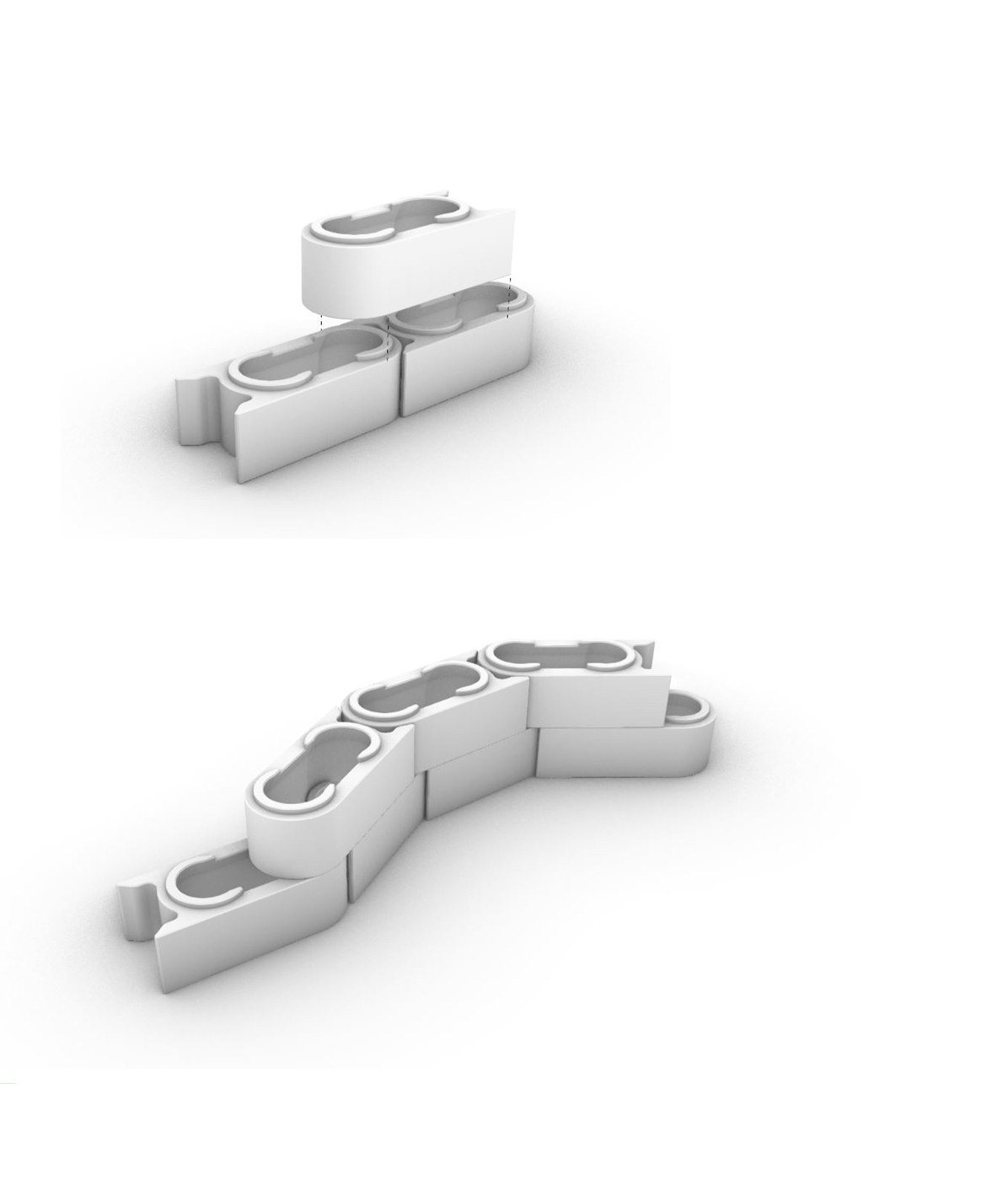

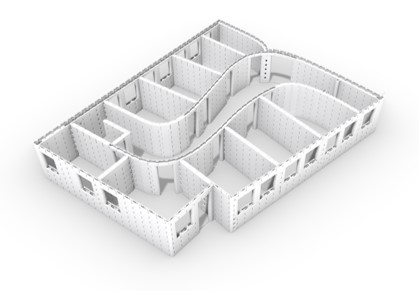

A combination of functionality and design.

Curved walls allow a maximum use of plot with multi-storey capability combined with asthetic and clean walls.

Flexibility – build, dismantle, reuse – everywhere

Changing circumstances can be easily addressed by the flexibilty of TwistBlocks. Dismantling, reusing and expanding are key features to fulfill a wide range of specific needs.

Outstanding design – modern elegance in every environment

The building technique offers the possibility of building round walls, so the building can meet almost every requirement.

Functionality – tangible benefits at lower costs

The TwistBlocks high-tech functionality includes fire safety, isolation and temperature management at lower costs than regular houses.

Our expertise

Includes construction especially in informal housing environments and slums

Houses

Sanitary facilities

Landscape design

Schools

The construction method has proven to work.

Start Somewhere’s pilot project – the construction of a school building for 400 children inside Kibera Slum, Nairobi – was realized in 2020 during COVID-19 crisis within the given framework both technically and financially. It was planned and coordianted remotely from Germany and built by residents of Kibera under the guidance of Start Somewhere.